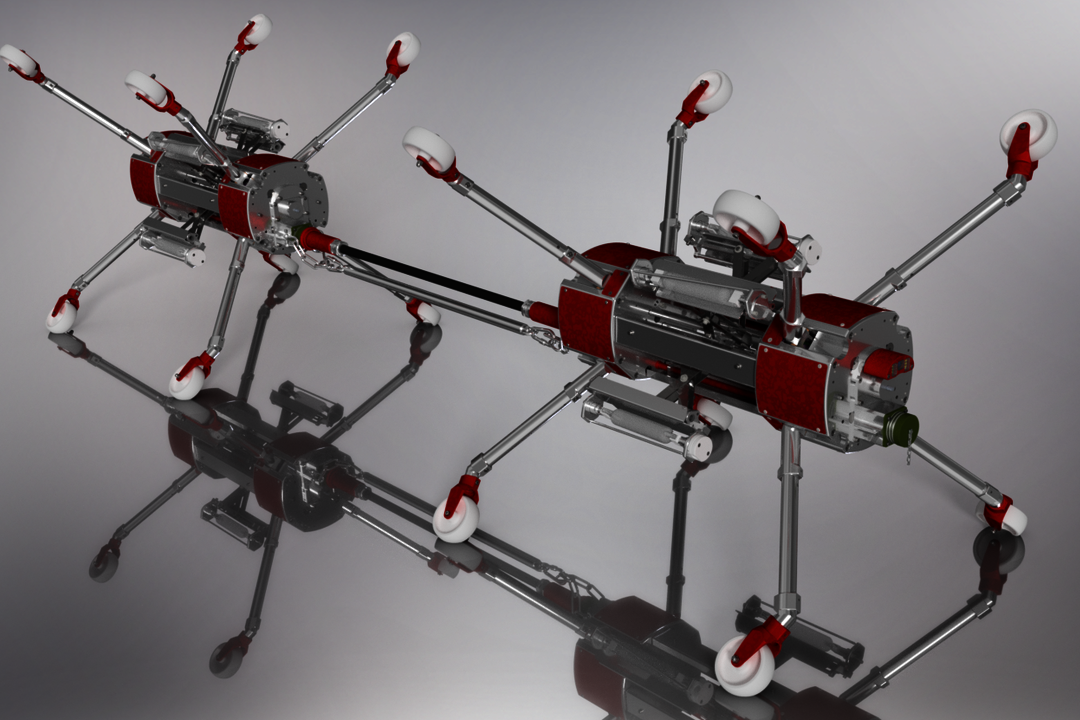

- Applicable in circular and egg-shaped profiles

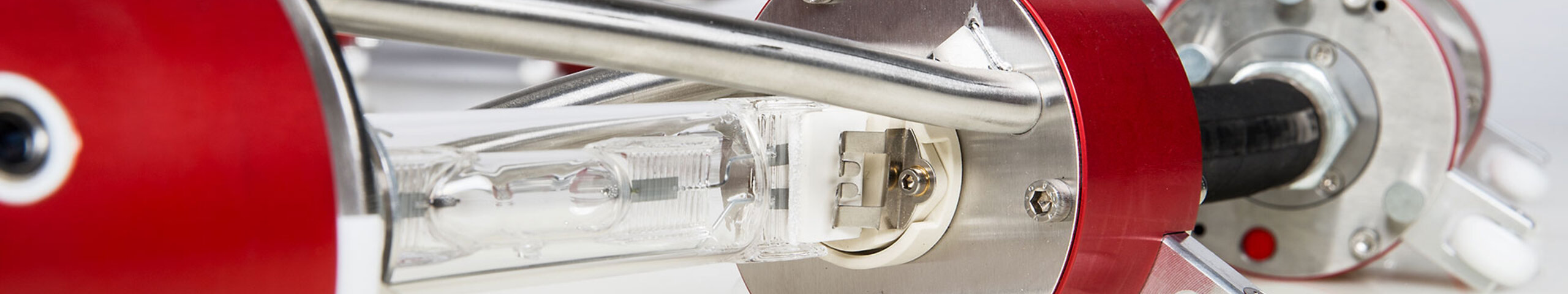

- Three integrated infrared sensors for the temperature measurement of liner surfaces

- Temperature sensor for the measurement of the ambient temperature in the liner

- Flexible design

- Rotating light retainers for minimum shadowing

- Camera cooling via built-in ventilator

- Front camera with horizontally placed image

- Heat-resistant Teflon wheels prevent the adhesion of resin particles

| Pipe dimensions | circular profile: 150-600 mm egg-shaped profile: 200/300 – 500/750 |

| Number of UV radiators | 8 pcs. |

| Number of cores | - |

| UV radiator output | 400 W or 650 W |

| Total output | 3,200 W or 5,200 W |

| IR sensors | 3 pcs. |

| Ambient air sensor | 1 pc. |

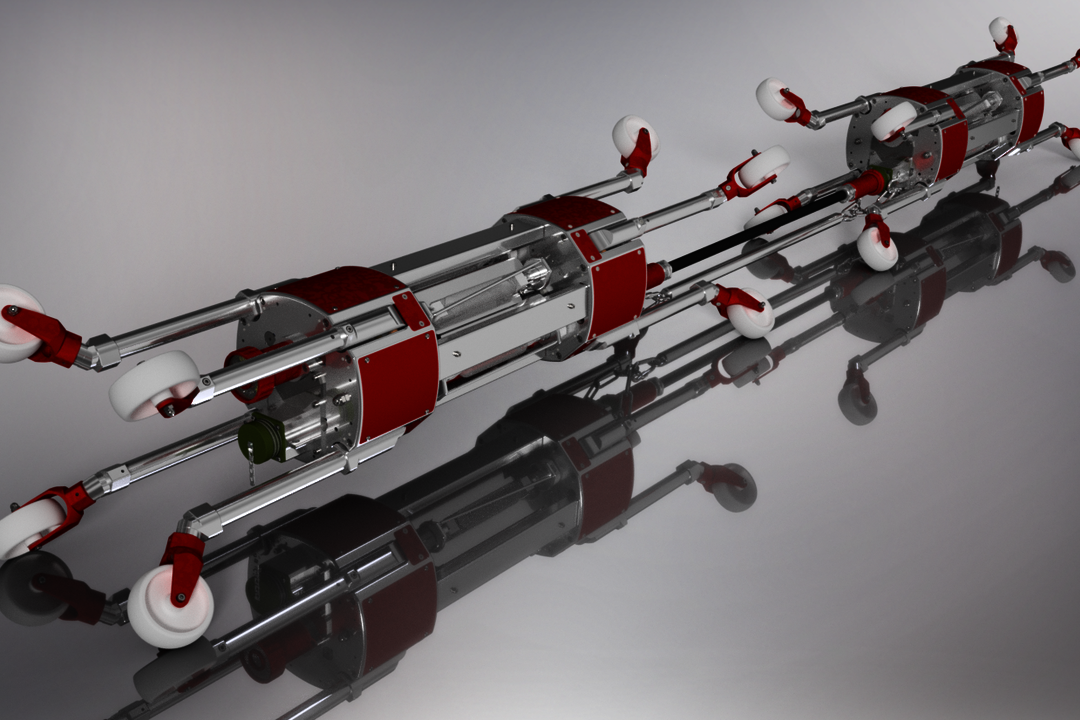

Resin-impregnated glass fiber inliners are efficiently cured with the SK1500 light chain. Applicable in circular 600-1,500 mm profiles. The chain consists of two identically constructed, self-sufficient cores. Each core has four radially arranged UV lamps each with 1000 watts. The installation of ldiverse "legs"of different lengths allows adaptation to different pipe diameters. Electrically moveable legs and radiators. When the chain is in the liner, legs extend and lift the cores up. At the same time, the radiators extend in the direction of the pipe wall in order to irradiate the laminate with as high a light intensity as possible. An indicator on the panel informs about the current extension position. With motor overload, the movements are stopped. Shortliners may also be driven with one core alone. Heat-resistant Teflon wheels prevent the adhesion of resin particles.

Optional

- Back-Eye camera

| Pipe dimensions | circular profile: 600-1,500 mm egg-shaped profile: 600/900 – 800/1,200 |

| Number of UV radiators | 4 per core |

| Number of cores | 2 pcs. |

| UV radiator output | 2,000 W |

| Total output | 16,000 W |

| IR sensors | 3 pcs. |

| Ambient air sensor | 1 pc. |

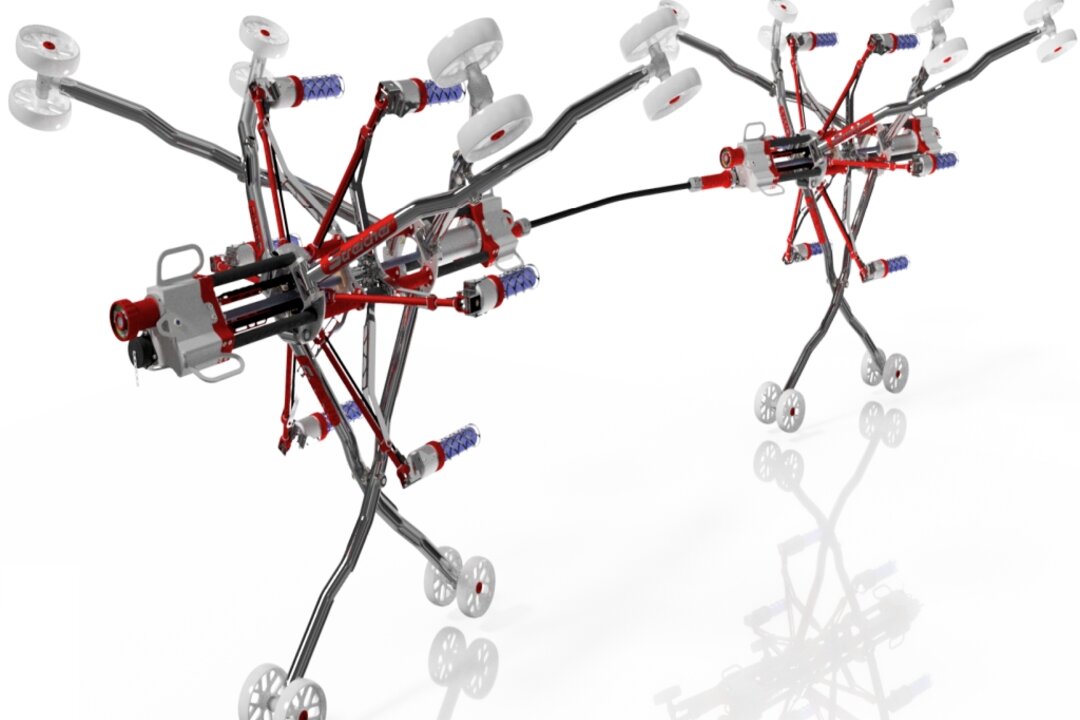

Like the SK600 and SK1500, the SK2000 is suitable for circular and egg profiles. It contains three integrated infrared sensors for measuring the temperature of the liner surface. The SK2000 also has temperature sensors for measuring the air temperature in the liner. It is characterised by two self-sufficient cores that are interchangeable.

This means that short liners can also be operated with just one core. The SK2000 is equipped with electrically extendable legs and radiators, which are protected from mechanical damage by lamp cages. Heat-resistant Teflon wheels prevent resin particles from sticking.

Optional

- Back-Eye Kamera

| Pipe dimensions | circular profile: 1,200-2,000 mm egg-shaped profile: 1,000/1,500 – 1,200/1,800 |

| Number of UV radiators | 6 per core |

| Number cores | 2 Stk. |

| UV radiator output | 2,000 W |

| Total output | 24,000 W |

| IR sensors | 3 pcs. |

| Ambient air sensor | 1 pc. |

SK600 / SK1500 / SK2000 packer

- Packer for all UV light chains

- Stainless steel design for circular and egg-shaped profiles

- Lateral connections or connections in cover available

- Each with a Storz B coupling, compressor claw coupling and pressure monitoring connection

- Cable and rope grommets made of heat-resistant and frictionless teflon

- Two or three piece modular designs for larger size pipes

- A camera is available for end caps of 400 mm and larger

![[Translate to English:] Streicher Kanalsysteme SK600](/assets/_processed_/0/2/csm_K1024_SK_600_03_bf24bde4dd.jpg)

![[Translate to English:] Streicher Kanalsysteme SK1500](/assets/_processed_/7/2/csm_SK1500_CAD__1__3d3a8cca2b.png)