The CL70 electric milling robot: innovation for efficient house connection processing

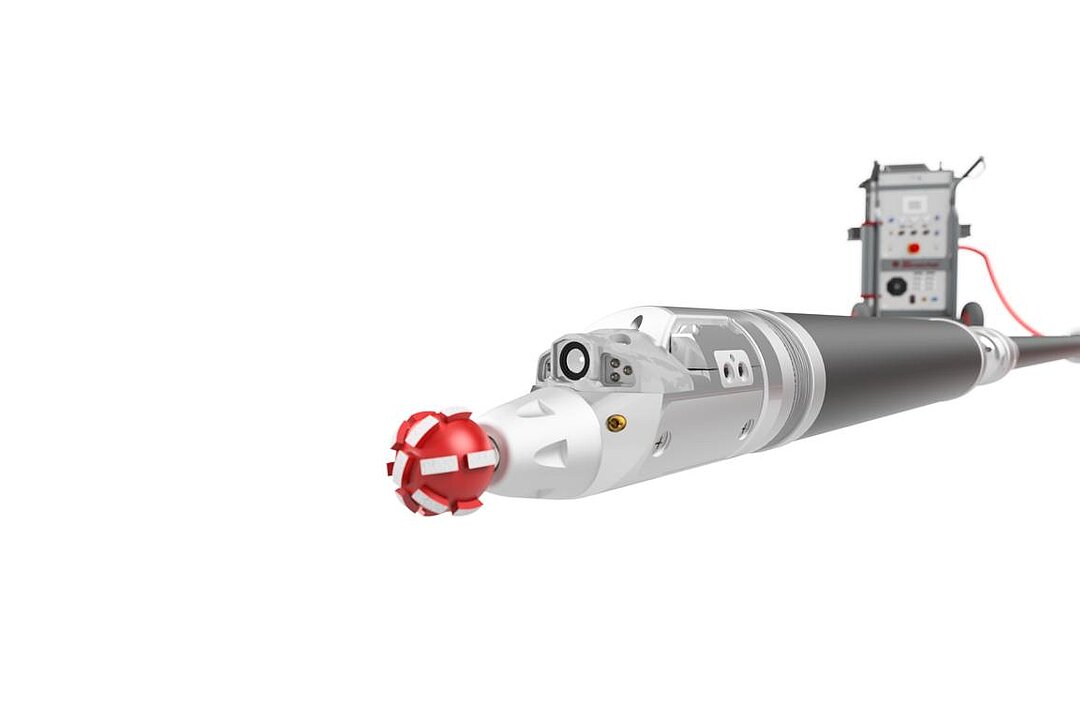

Since its market launch two years ago, our CL70 electric milling robot (from DN75) has established itself as a leading product in the field of house connections. Thanks to its advanced technology and sophisticated design, the CL70 offers unrivaled performance and reliability in the processing of house connections.

The CL70 effortlessly negotiates 90° bends and masters dimensional leaps up to DN250 without the need for complex conversion work, thanks to its extremely flexible tensioning bladders and pneumatic muscle feed. As an option, the robot can also be used in pipes up to DN300 with the push carriage.

An innovative concept is the modularity: the user can assemble the system from different case units as required. The most compact configuration consists of the milling robot and the control unit with battery, which keeps investment costs low. For those who want to use the full potential of the robot system, additional options such as a compact compressor case, a tool case and an ergonomic transport trolley are available.

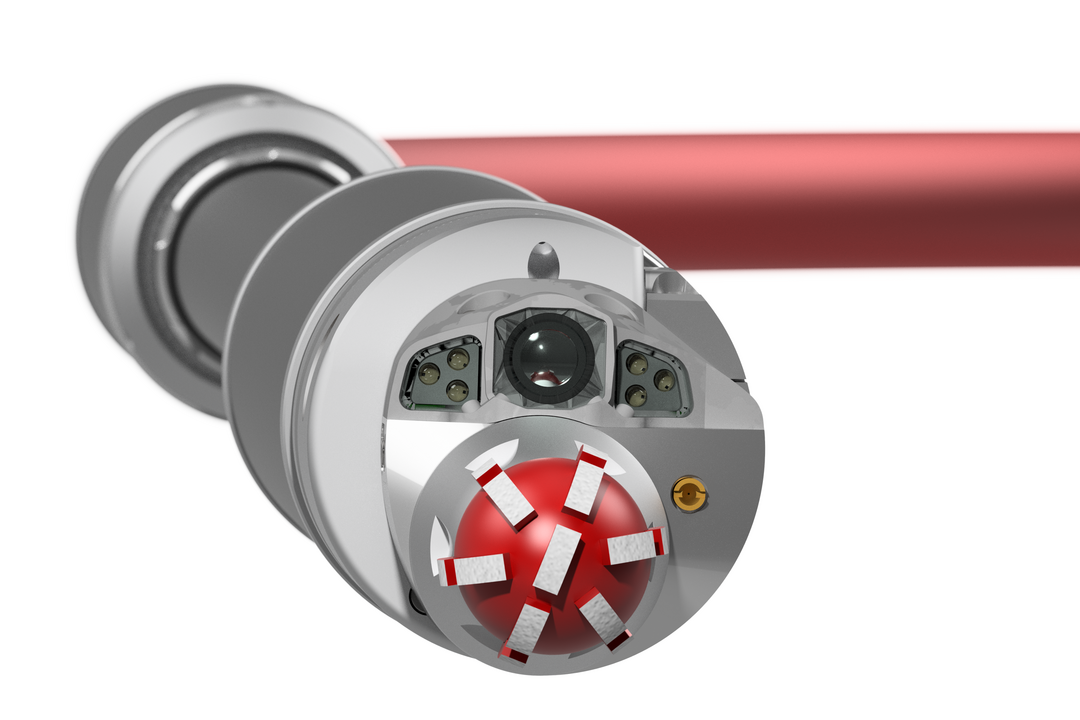

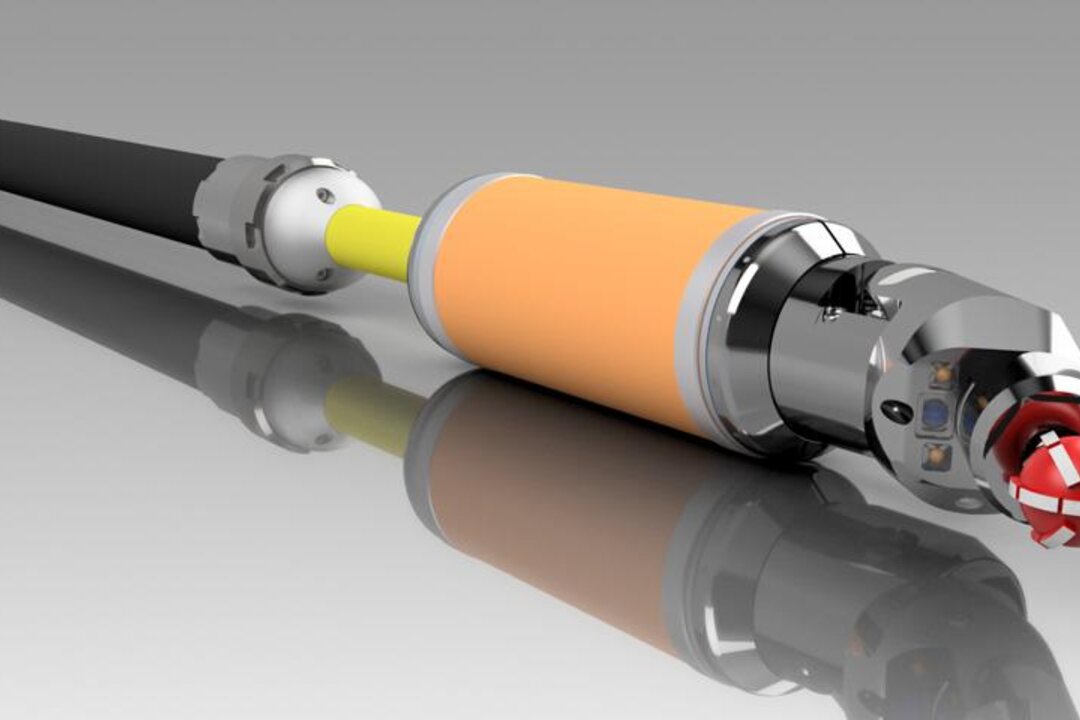

At the heart of the milling system is an efficient and powerful 800W water-cooled electric motor. The entire milling head is protected against the ingress of water by a permanent internal coating. A high-resolution HD camera delivers razor-sharp images in real time, which can be easily documented using the integrated recording function of the control unit, without the need for additional software.

Further details

- Modern: The latest technology ensures the highest possible productivity & reliability

- Modular: freely combinable case system offers the right equipment for every challenge

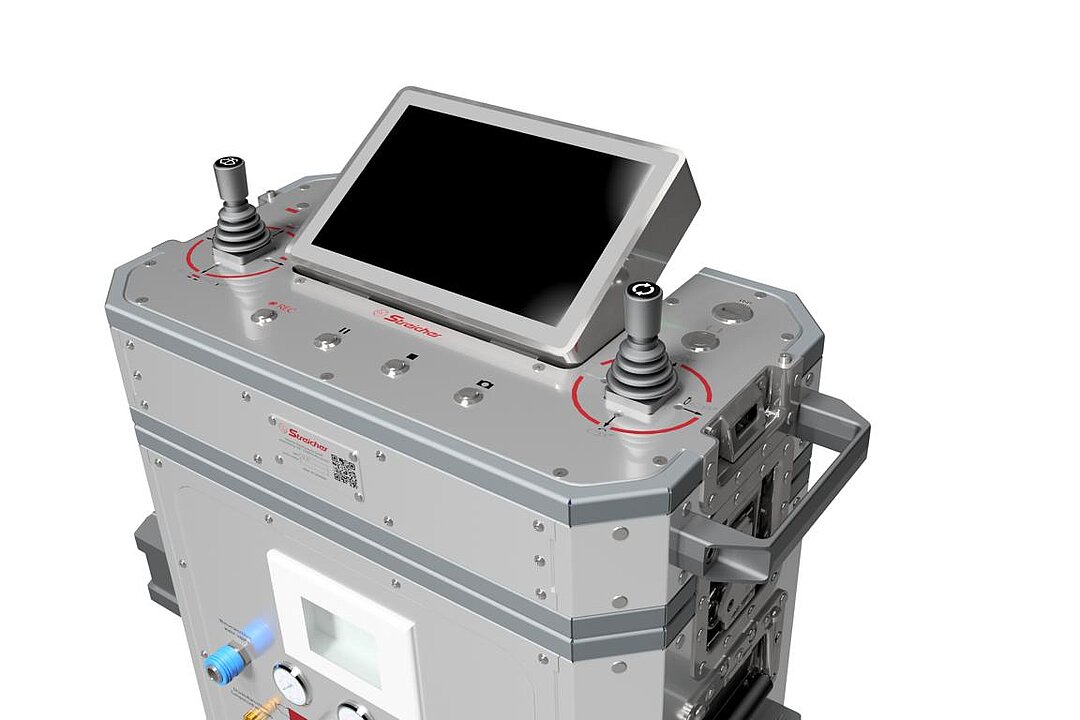

- Mobile: equipment trolley with docking function for the control unit enables maximum flexibility and ergonomics

- 2x45° (1x90°) pipe bends do not present an obstacle when retracting or extending

- Centric clamping in the tube

- HD color camera module with adjustable LED lighting

- Integrated water tank with 5 liters

- Camera cleaning with water and air

- Operation via an equipment cart with joystick and touch panel (PLC control)

- The equipment trolley is equipped with all the necessary tools for use

- High-contrast monitor

- Sensors and display messages inform the user about the current status of the robot system

- Water-cooled milling motor

- The scope of delivery includes 4 rechargeable batteries and a quick charger (batteries fully charged within 45 minutes)

- The robot system is pressurized to 1 bar

- Recording device with integrated hard disk (output to USB)

- Ready for use without major effort or conversion

- Accessories

- Pneumatic feed mechanism (muscle)

- Extension cable (10 m or 20 m)

- Equipment trolley to hold the individual modules

- Compressor

| pipe dimension | DN 75-250 |

| weight (robot only) | 5 kg |

| swivel angle | 600° |

| feed | pneumatic |

| milling arm drive | electric |

| cutting motor drive | electric |

| milling motor power | 800 W at 17.000 rpm |

| length of supply cable | 20 m (40 m) |

Our CL50 milling robot offers the perfect solution for house connection sewers from DN 60. With its compact design, it is the only milling robot of its kind that can work in this nominal width - a unique selling point.

The CL50 effortlessly masters several 90° pipe bends and can move precisely thanks to its swivel angle of over 600°. Movement is driven by the supply line, an additional sliding eel or the optional stepless “muscle feed” feed mechanism. Retraction is achieved by pulling on the supply line and a cable on the milling arm.

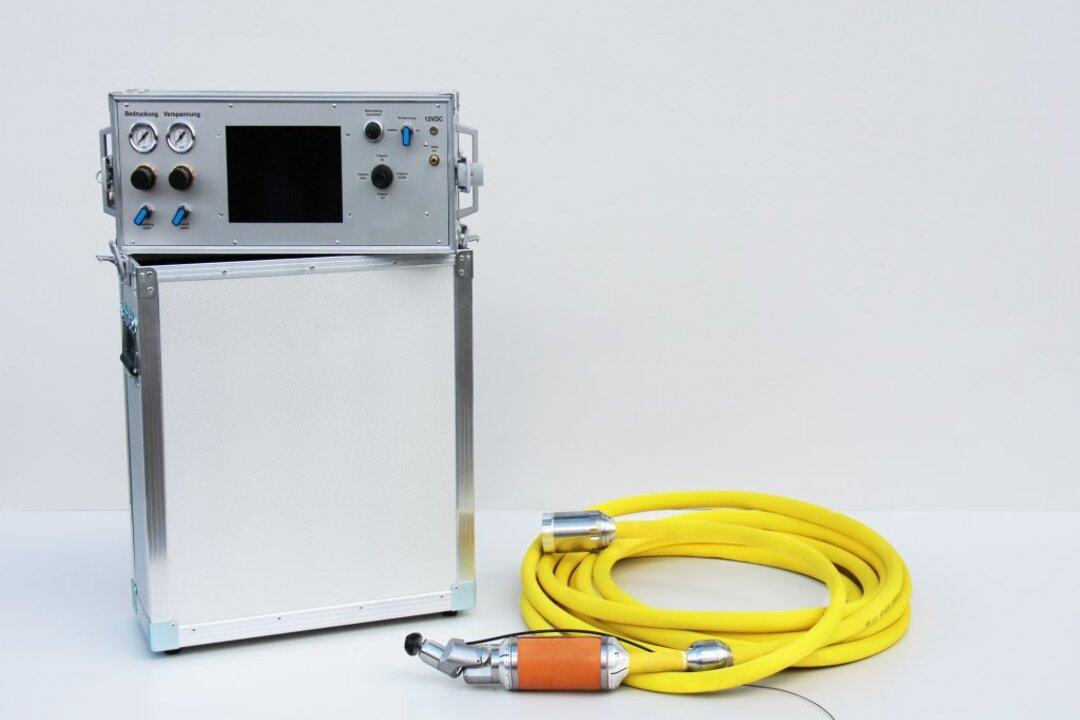

A tension bubble ensures stability in larger pipes, while a color camera and adjustable LED lighting provide a clear view. The camera is cleaned using compressed air and water in combination with the equipment trolley, without the latter, using only compressed air.

It is usually conveniently controlled via a portable control unit (CL50 Compact) or the mobile equipment trolley (CL50). Operation is possible either via a rechargeable battery or a mains adapter.

The CL50 can also be operated via a CL80 equipment trolley.

Accessories

- Extension cable 12.5 m / 25 m / 37.5 m

- Battery operation possible if 230 V AC voltage is not available

- Equipment trolley

- Muscle feed

- Equipment trolley:

- Height and tilt adjustable

- Side storage space for robot or muscle feed

- Push handles can be folded down during operation

- Weight 30 kg

- 2 L water tank for camera rinsing

- Integrated air drying unit

- Built-in rotary distributor for feeding through all media

- Pneumatic tires

- 2 exchangeable batteries

| Pipe dimensions | 55-125 mm (with accessory up to 150 mm) |

| Weight | 2,5 kg |

| Feed | rod / muscle |

| Cutting arm drive | electrical |

| Milling motor drive | pneumatic |

| Milling motor output | 500 W at 20,000 rpm |

| Light diameter | 53 mm |

| Length of supply cable | max. 37,5 m |

The CL80 milling robot is ideal for milling in house connection sewers from DN 85-200 - with sliding carriage up to DN 300.

A color camera with LED lighting is located at the front of the milling head. The camera is cleaned at the touch of a button, using either air or water. The robot is operated via a removable control box attached to the equipment trolley. An anti-glare, high-contrast screen, touch display and joystick are integrated into the lid of the control case. Sensors in the case and robot warn the operator in the event of moisture ingress and thus protect the system from premature failure. The robot can be adapted to the respective pipe diameter by simply changing the clamping bladders. The supply line of the CL80 is available in 10 m and 20 m lengths.

Bladder feed or muscle feed:

The automatic, alternating inflation and deflation of the tensioning bladders in conjunction with the back and forth movement of the feed means that even pipe sections that are difficult to access can be overcome. Even 90° pipe bends are no obstacle. The way it moves also ensures that it can be extended out of the sewer. The milling arm can be raised and lowered precisely and rotated over a wide range of 630°. A clamping bubble with a lamella mechanism centers the milling head in the pipe. The powerful, pneumatically driven milling motor easily removes even large deposits or building iron.

The muscle feed is an alternative to the bladder feed of the CL80. It can be integrated between the supply line and the milling head and offers a stepless retraction movement. 45° pipe bends do not pose an obstacle when retracting or extending. It is operated with the existing control system and is ready for use without any additional accessories. The muscle feed reaches the damaged area independently or with the help of a sliding eel. The great advantage is that for the first time, milling work is possible with stepless advance. The difference in length between retracted and extended position is 20 cm.

- Pipe dimensions: DN 85-200

- Weight approx.: 4 kg

Accessories

- Extension pipes available in 10 m or 20 m, lengths up to 100 m possible

CL80 push trolley up to DN300

| Pipe dimensions | DN 85-200 mm (with accessory 300mm) |

| Weight | 3,8 kg |

| Feed | pneumatic / rod |

| Cutting arm drive | electric |

| Milling motor drive | pneumatic |

| Milling motor output | 750 W at 20,000 rpm |

| Light diamter | 76 mm |

| Length of supply cable | max. 50 m, max. 100 m (without bubble feed) |

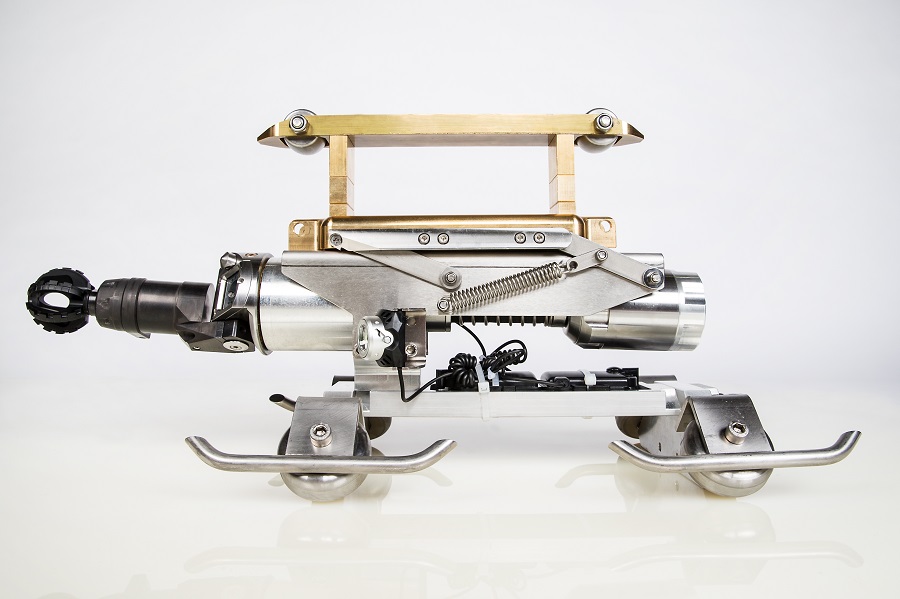

CL80 sliding wagon

This accessory makes the household connection robot CL80 a multi-tasking robotic system for an increased number of applications. The pneumatic cutter is also suitable for centrical milling tasks in 190-300 mm duct systems and is positioned at the needed location by means of a fiber-glass rod. Due to the integrated tension and lateral lighting, precise milling tasks are ensured in a work area with optimal illumination. All required parts are contained in the sliding wagon set and can be adapted to different pipe dimensions.

- pipe dimensions: 190-300 mm

- weight: 7.5 kg