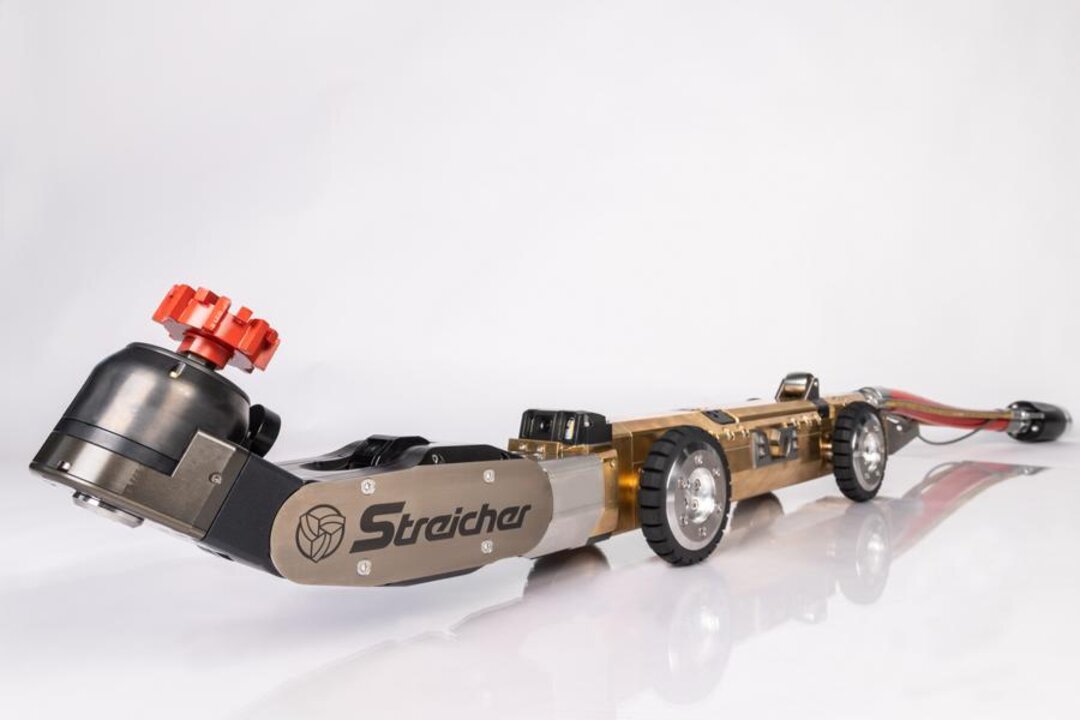

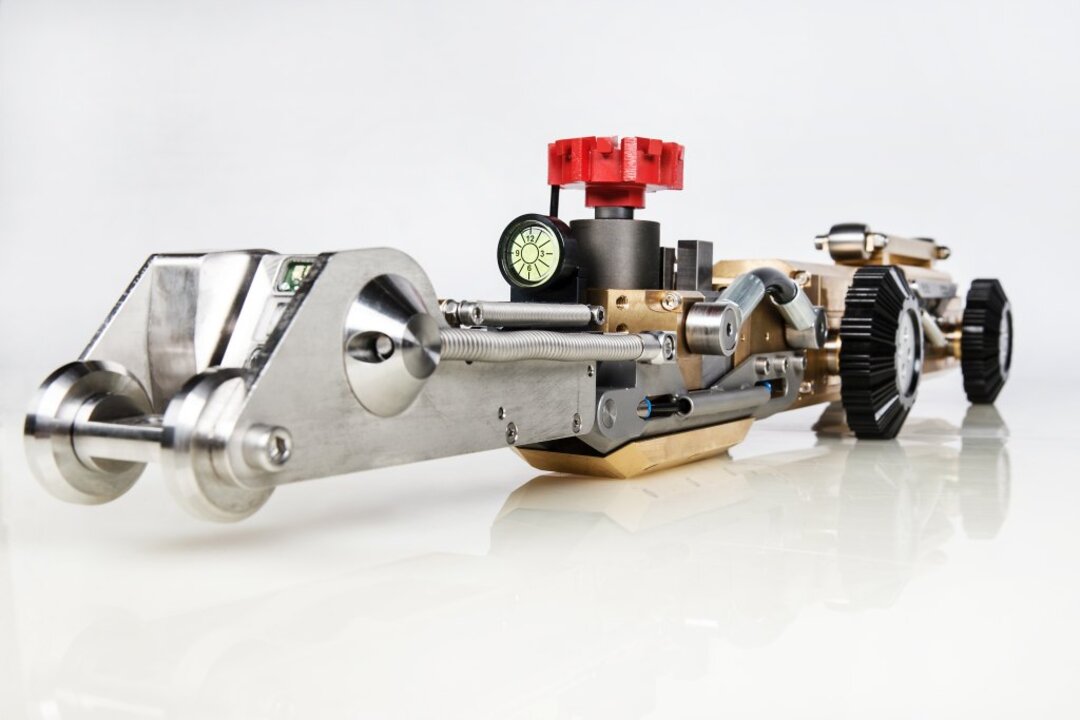

With our electrically driven milling robot EF130, we as a manufacturer offer both products (EF130 and EF200) a consistent and future-oriented portfolio of electric work robots from DN140 - DN400. As usual, the robust construction is designed for the toughest requirements on the construction site. In addition, the EF130 offers all the conveniences that are expected from electrical machines (no hydraulic unit, low background noise, handy supply hose, easy maintenance). In contrast to its hydraulic predecessor, the HF130, the new electric EF130 offers a number of other advantages: the milling arm has a third degree of freedom and a second, swiveling camera, as already known from the EF200.

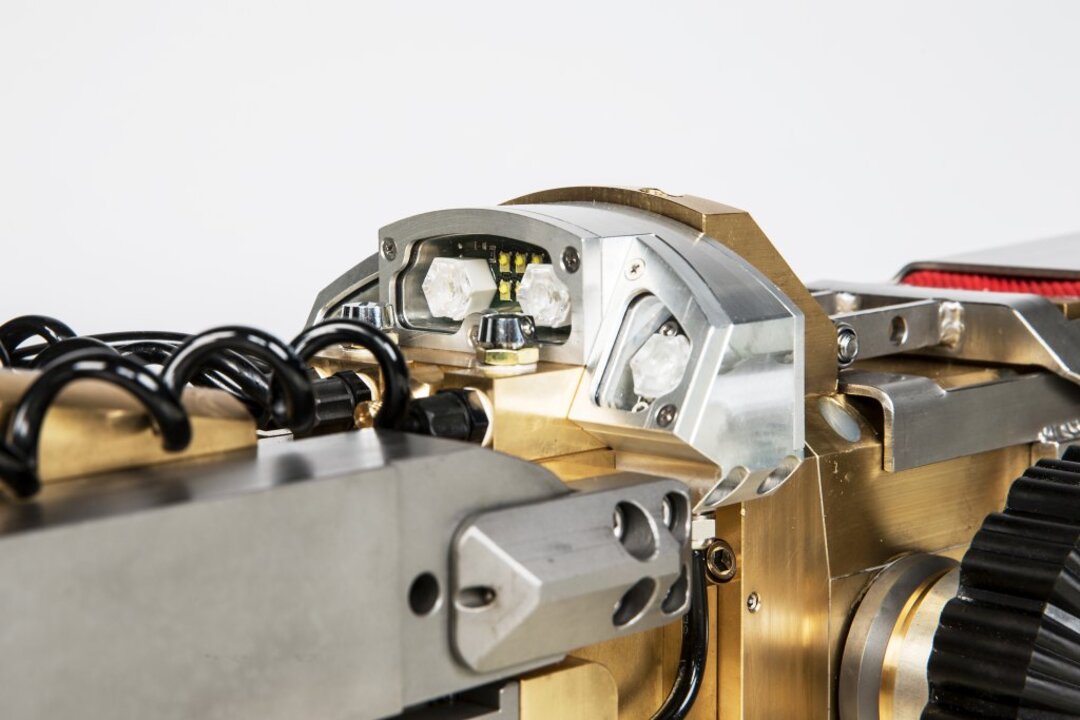

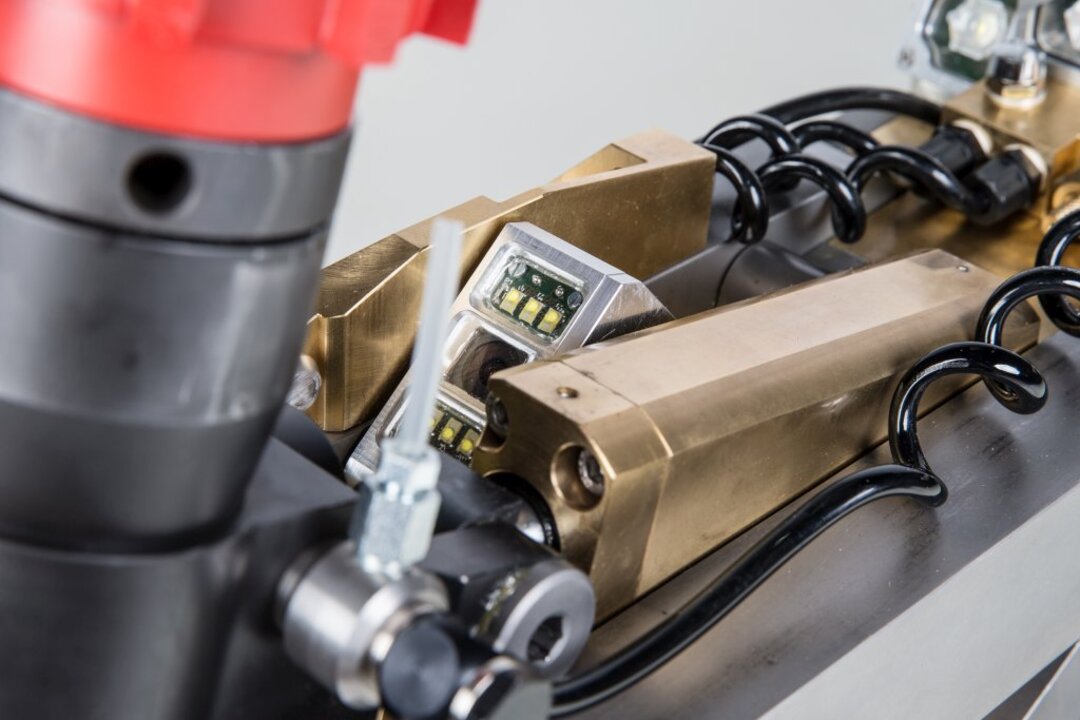

In-house developed milling motor

The EF130 has an in-house developed and water-cooled 1,8 kW electric milling motor, which is suitable for continuous operation in sewers.

Individual vehicle installation

As a fully electric robot system, the EF130 is integrated into commercial vehicles according to customer requirements. A typical and common configuration results withthe Daily from Iveco or the Sprinter from Mercedes-Benz. Lithium-ion batteries in combination with photovoltaic systems on the roof enable highflexibility and self-sufficiency. The EF130 is compatible with the EF200 controller and most EF200 and HF130 interchangeable parts.

optional

- egg-shaped profile support

- renovation packer connection

- ultra-high pressure jetting

| pipe dimension | circular profile: 140-300 egg-shaped profile: 200/300 |

| weight | 45 kg |

| drive | electrical |

| cutting arm drive | electrical |

| cutting motor drive | electrical |

| cutting motor output | 1,8 kW |

| length of supply cable | 150 m |

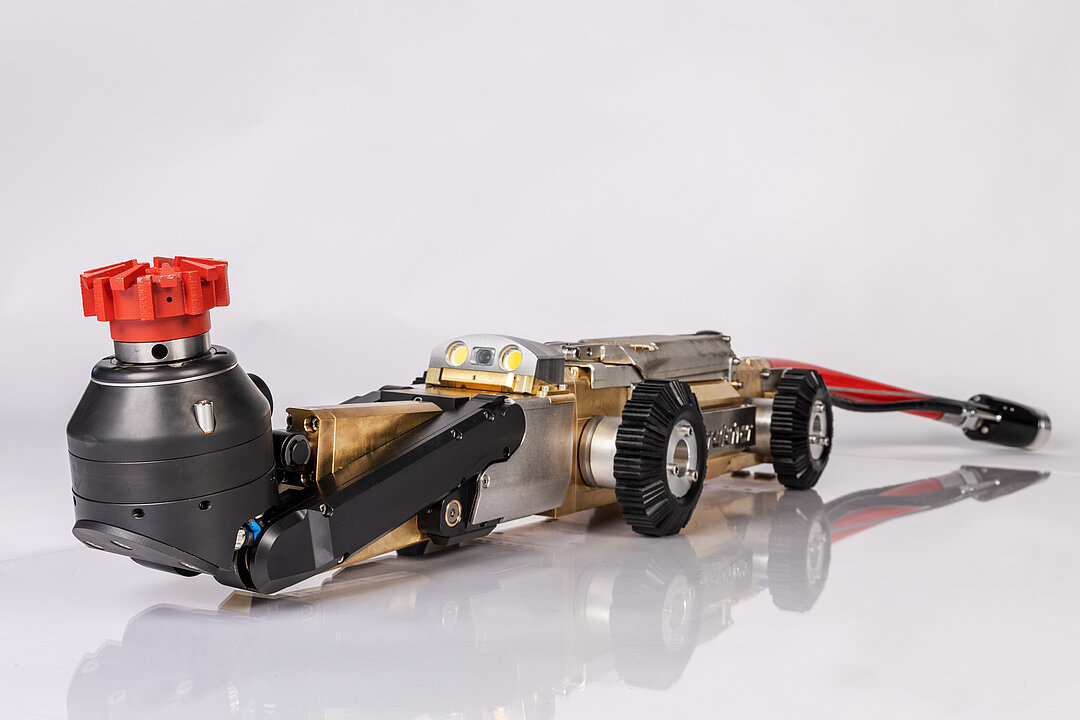

In the course of the development of a modern energy society and the associated wish to reduce emissions, an electrically actuated milling robot was designed. Due to the high weight and the strong traction drive in connection with the tension against the upper pipe wall, the robot has an enormous pulling force. This makes it possible to draw a supply cable of up to 150 m. The 3-axis milling arm is mainly moved hydraulically. The two milling motors with 2 kW and 4 kW power are connected to the 3-axis milling arm. Because of a water cooling, it can be heavily overloaded in continuous operation. The loss of water splashes through the axis and cleans the work area. The robot has two cameras each with dimmable lighting. One camera is pivotally mounted between the two milling arms, the other is fixed on top of the milling arm. If the cameras are contaminated by milling dust, nozzles and wipers enable effective cleaning.

optional

- additional lighting for 250 mm pipe and larger

- trowel unit

- chassis

- egg-shaped profile support

- renovation packer connection

- ultra-high pressure jetting

| pipe dimension | circular profile: DN 200–800 mm (with accessories to 1,200 mm) egg-shaped profile: DN 250/375–800/1,200 |

| weight | 85 kg |

| drive | electrical |

| cutting arm drive | electrical/hydraulic |

| cutting motor drive | electrical |

| cutting motor output | 4 kW |

| length of supply cable | 150 m |

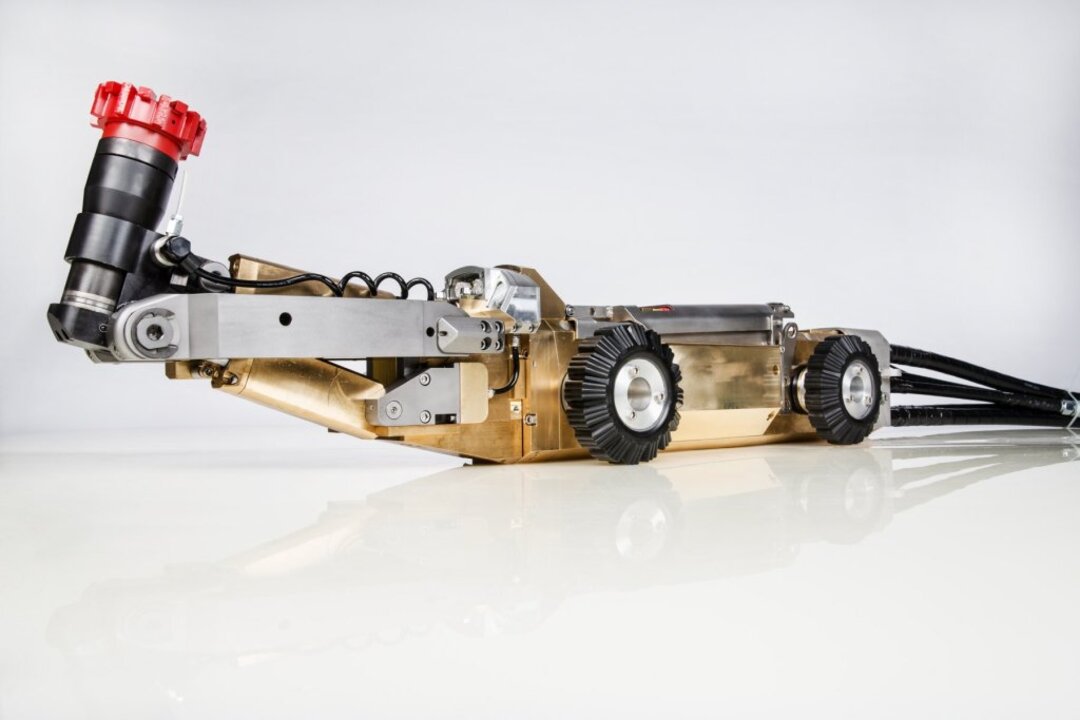

The extremely compact built, self-propelled robot HF200 is used for milling in the main channel. The arm of the robot is comparable to that of an excavator and enables a three-axle work and is great for milling within the inlet area. To ensure maximum stability and thus the value retention of the robot, almost all wearing parts are made of hardened steel. Also, the cable and hose connection is protected by a sturdy V2A sheet metal. The hydraulically driven milling motor ensures high removal rates at low speed and high torque. The camera glasses can be cleaned by water nozzles and wipers.The pneumatic clamping and the different wheel sets increase the traction when entering the channel. Possible cable breaks can be quickly repaired by replacing the first two meters of the pluggable supply line.

Also, the internal pressure is constantly displayed.

optional

- additional lighting for 250 mm pipe and larger

- trowel unit

- chassis

- egg-shaped profile support

- protective guides for supply cables

- ultra-high pressure jetting

- renovation packer connection

| pipe dimensions | circular profile: 200-800 mm (with accessory up to 1,000 mm) egg-shaped profile: 250/375 – 800/1,200 |

| Weight | 90 kg |

| Drive | electrical |

| Cutting arm drive | hydraulic / electric |

| Milling motor drive | hydraulic |

| Milling motor output | 2 kW at 2,500 rpm |

| Length of supply cables | 75 m and 100 m |

Despite its slim design, the drive and the lifting movement of the milling motor is hydraulic. The guides of the lifting mechanism keep the robot absolutely stable. Depending on application, the milling motor can be mounted perpendicular to the axis of the pipe when working radial or horizontally for working forward. Like the HF200, it also has pneumatic clamping, a continuously variable drive and differently designed wheelsets. Without conversion work, it can be connected directly to the supply line of the rehablilitation vehicle. The robot type is automatically detected by the controller and the user interface is changed accordingly.

optional

- protective guides for supply cables

- additional weights with 27 kg and traction lever

- for an optimal traction and drive in the duct system

- front head milling device

| Pipe dimensions | circular profile: 130-300 mm |

| Weight | 55 kg |

| Drive | electrical |

| Cutting arm drive | hydraulic / electric |

| Milling motor drive | hydraulic |

| Milling motor output | 2 kW at 2,500 rpm |

| Length of supply cables | 75 m and 100 m |

HF200 / EF200 Egg-shaped profile support

The egg-shaped profile support completes the chassis, providing a comprehensive system that meets the highest demands with regard to precision and quality. The support ensures secure positioning of the robot during the milling tasks. The support wheels are adjusted to the various egg-shaped profiles with cross-bars and set-screws.

- Suitable for egg-shaped profiles

from 250/375 – 800/1,200 - Used in combination with the chassis

HF200 / EF200 trowel unit

After the milling tasks are completed, the trowel unit is used for the direct renovation at the respective area with the same robot. The trowel unit is filled with an epoxy resin mixture and mounted onto the HF200 or EF200. The filling compound is then pressed out at the damaged area and spread with the trowel.

- 2 liter reservoir for epoxy resin LED signal lamps warn the user on the remaining level

- various trowel attachments for longitudinal and cross-sectional cracks

- spring-loaded trowel for a clean and uniform application

- foldable for easy entry into the duct system

HF200 / EF200 chassis

Chassis are easily combined with the robot, facilitating the access to the damaged areas in duct systems with circular or egg-shaped profiles. The wheelsets are directly driven by the robot via a drive gear. The design of

the chassis allows the movement of the rotating axis of the cutting arm towards the pipe center, so that milling tasks can be performed without adjustments.

Chassis are available in the variants 600 and 1,000

- Chassis 600 for 450-600 mm pipes

- Chassis 1000 for 700-1,000 mm pipes and for egg-shaped profiles 500/750 – 800/1,200