Connection renovation with the EL400drive grouting system for DN 250-600 from Streicher

For more than 30 years, the ‘EL’ lateral connection renovation system from Streicher has been used for lateral inlet renovation. Mortar or epoxy resin is used as the grouting material. The system was recently revised for the benefit of operators.

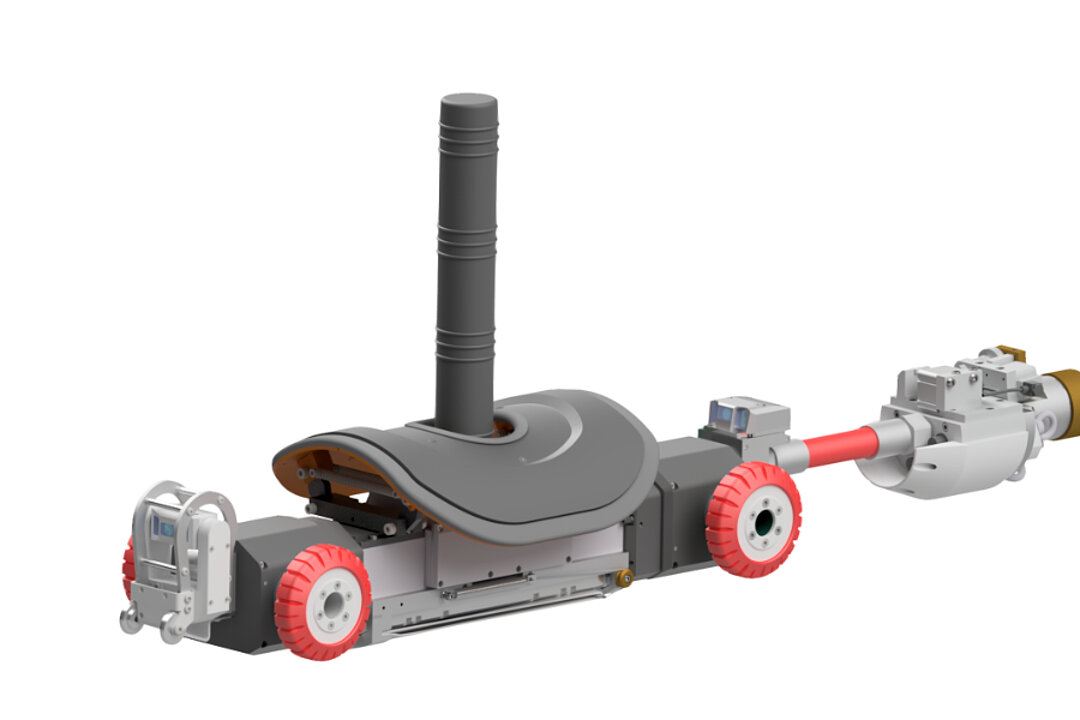

As the name ‘drive’ suggests, the biggest innovation is the integration of a powerful travelling drive, which means that the renovation robot no longer has to be laboriously pulled to the damaged area. The previous cameras have been replaced by high-resolution HD cameras as part of the overhaul.

Product description - functions and advantages

The ‘EL system’ was the first product with which Streicher Kanalsysteme entered the sewer rehabilitation industry in the early 1990s. Since then, the machine has established itself as a reliable tool for the trenchless, efficient and professional rehabilitation of side inlets in the main. Recently, the system has undergone considerable further development and is now self-propelled, which significantly increases efficiency and flexibility for operators.

The EL400drive not only has an independent drive, but is also equipped with a 180° rotating renovation shield, which means that horizontal laterals can also be renovated. The robot has a 70 metre long supply cable, which is a further advantage, as this allows it to process distant locations and several successive inlets.

Once it reaches the damaged area, the rehabilitation shield is pressed itself against the pipe wall of the main pipe with over 1,200 kg. A sealing bladder is then rolled out into the side inlet using the integrated winch and inflated to seal the inlet. When rehabilitating with mortar, a mortar hose up to 60 metres long runs from the rehabilitation vehicle to the robot. This hose is then used to clean the formwork with water and check whether the rehabilitation shield is in clean contact with the pipe wall and is completely sealed.

Another special feature is the independence between ‘mixing mortar’ and ‘pumping mortar’: the injection mortar is mixed via a permanently installed mixing unit in the rehabilitation vehicle and emptied into a hopper mixer with a connected mortar pump via a lifting mechanism. From there, the mortar is pumped to the robot and injected into the formwork. The advantage of this separate process is that new mortar can be mixed at the same time as the existing mortar is being pumped. A pressure switch indicates when the mould is completely filled. After a short waiting time, the mortar hose is disconnected, pulled back and cleaned.

When using resin, the material, which generally consists of two components, is usually mixed in a container. For higher consumption, a press-out unit (Streicher AP4) is suitable, in which both components are combined electrically via a compulsory mixer. The mixed, homogeneous resin is then filled into a cartridge attached to the front of the robot and transported to the damaged area. There, the material is pneumatically pressed into the damaged area.

In contrast to the resin process, injection with mortar enables continuous and unlimited refilling of the material, which represents a considerable advantage over comparable processes.

The recommended mineral grouting material is a cement-bound, plastic-modified, single-component injection mortar from Th. Scholten GmbH & Co. KG, which fulfils the requirements for XA3 in accordance with DIN 206-1.

During development, Scholten attached great importance to a fast formework time in order to realise a rapid recommissioning of the structures in a practical manner. The formwork/shield can usually be removed 30 minutes after pumping has started. This is another major advantage for cost-effective working and rapid construction progress.

The fine-grained mortar, which is only mixed with water, ensures very good pumpability and penetrates deep into small cracks and cavities, resulting in a form-fit, durable bond, optimum sealing and a long-lasting, shrinkage-free result. It is also possible to fill larger cavities without any problems, even under water.

Two high-resolution cameras are installed to monitor the process and precisely position the robot: an electrically swivelling camera at the front and a fixed camera at the rear of the robot. The swivelling camera not only allows the rehabilitation process to be optimally monitored, but also offers the option of looking directly into the inlet from below as well as in the direction of travel to the next damaged area. This is often required as proof of successful rehabilitation.

Like all Streicher products, the EL400drive is continuously pressurised with air to protect it from water ingress. Thanks to different bubble sizes and shapes, even damaged areas further back can be effectively sealed.

The end result is water impermeability in accordance with DIN EN 12390-8 and the renovated areas are waterproof, even against pressing groundwater.

Streicher focusses on customer satisfaction and enables all existing EL systems to be converted to the new EL400drive system. In addition, the existing renovation shields and bracing bladders are compatible, which significantly reduces the investment costs for an upgrade.

This renovation process is unique on the market and is installed in vans, lorries and trailers.

| Pipe dimension | Circular connection: DN 250-600 / lateral connection: DN 70-200 |

| Weight (only robot) | 100 kg |

| Drive | electric |

| Swivel drive | electric |

| Contact preassure | 1.200 kg |

| Lenght of supply cable | 70 m |

Fully automatic squeeze out and mixing unit AP4

Fully automatic squeeze out and mixing unit for four bags

of resin and hardener.

- electrically driven via 230 volt alternating current

- better dosing in comparison to pneumatic squeeze out and mixing units (no dripping)

- low costs for compulsory mixers

- much smaller than other pneumatic squeeze out and mixing units

- dimensions (W x D x H) 305 x 240 x 1120 mm

- spring-supported lid unit for an easier change of bags

- very high extrusion force

- 4 tubular bags with 700 ml