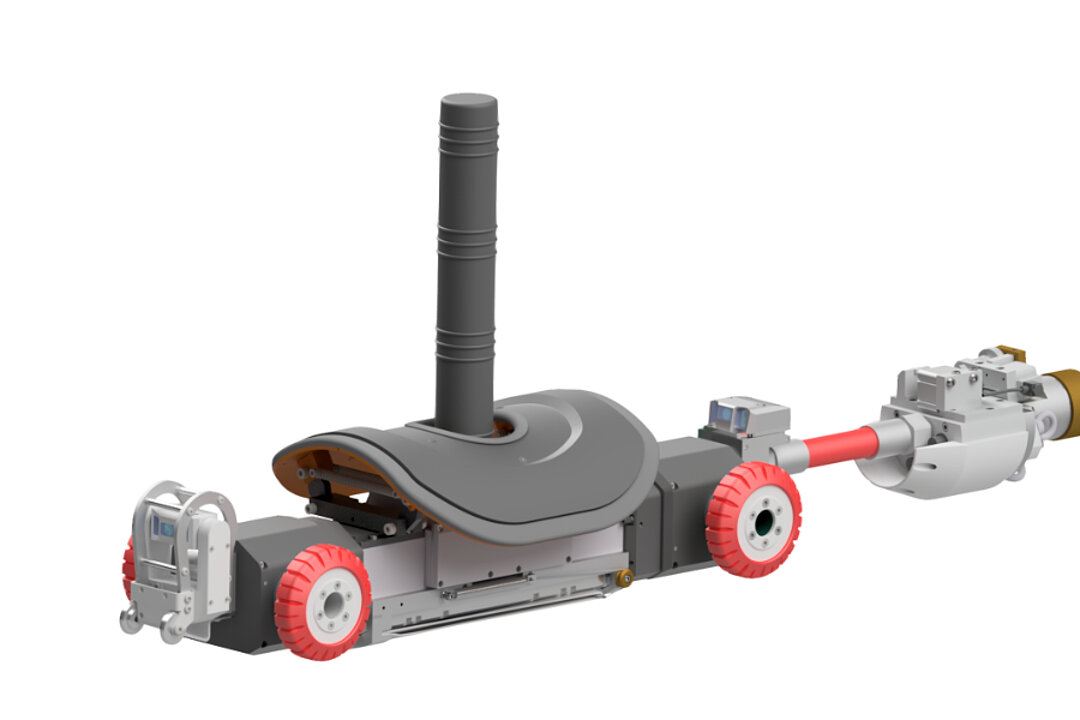

The EL400drive is the further development of the EL300. Thanks to this optimization, our system is now self-propelled, which increases efficiency and flexibility for our customers many times over. The system is used for trenchless, efficient and professional renovation of side inlets such as house connections. Side inlets can discharge at an angle, tangentially or horizontally. Even recessed, badly broken or poorly connected inlets can be renovated without any problems.

The grouting mortar is mixed and transported to the damaged area through a pipe using a concrete pump. In contrast to other renovation methods, where the supply of grouting material in the cartridge is limited, here material can be refilled without limit and pumped to the damaged area.

The bladder is first rolled up on a winch and, once the robot is correctly positioned, pushed into the side inlet by rolling it off. The renovation shield can be rotated by 180°, which means that horizontal inlets can also be renovated.

Two cameras are available for process monitoring and positioning, one at the front and one at the rear. The robot is permanently air-coated and therefore protected against the ingress of water. Different bubble sizes and shapes enable sealing even for damaged areas that are far back. Mortar is used as the grouting material.

| Tube dimensions | circular profile main pipe: 250-600 mm service connection: 70-200 mm |

| Weight | 100 kg |

| Drive | elecztric |

| Swivel drive | electric |

| Contact pressure | 12,700 N |

| Length of supply cable | 70 m |

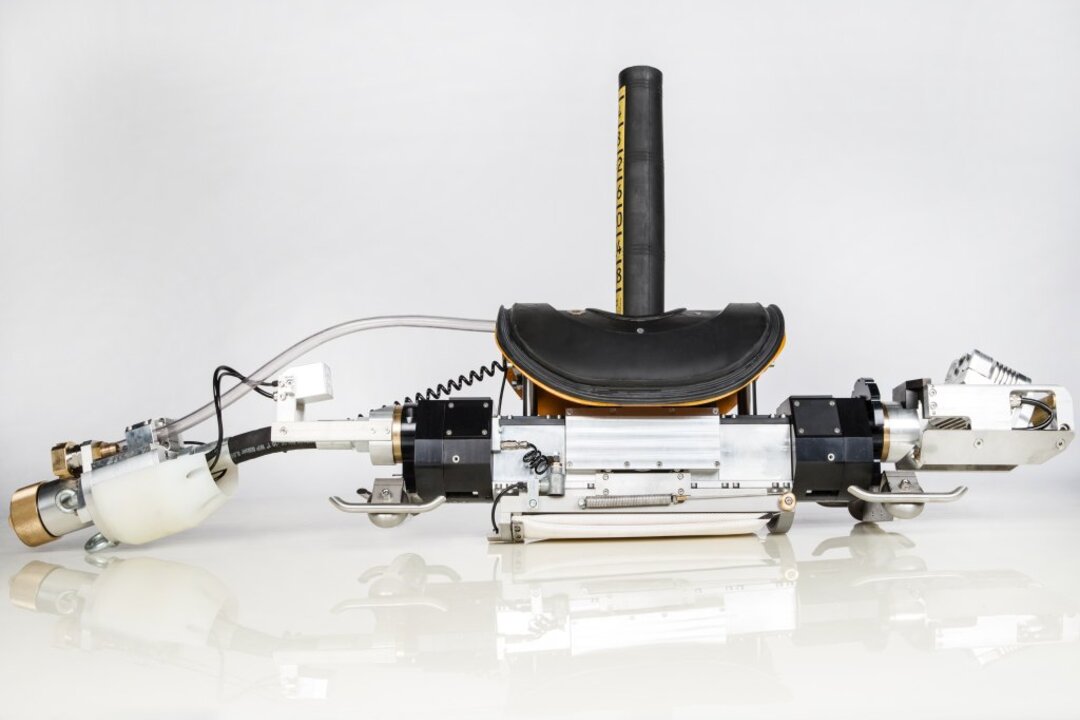

The EL300 is used for the trenchless, quick and professional renovation of service connections. The system is specifically appropriate for recessed, chipped or poorly plastered lateral inflows. Also inclined or tangentially discharged, lateral inflows are no problem. The integrated concrete pump transports the mortar mixture via a hose to the damaged area. Contrary to the trowel procedure with a limited stock of filler in the reservoir, the mortar is continuously pressed into the damaged area, until filling up all spaces. Even in case of increased water infiltrations and mortar applications, the supports can be prepared for

grouting repair. Both mortar and epoxy resin can be used.The EL300 is used for the trenchless, quick and professional renovation of service connections. The system is specifically appropriate for recessed, chipped or poorly plastered lateral inflows. Also inclined or tangentially discharged, lateral inflows are no problem. The integrated concrete pump transports the mortar mixture via a hose to the damaged area.

Contrary to the trowel procedure with a limited stock of filler in the reservoir, the mortar is continuously pressed into the damaged area, until filling up all spaces. Even in case of increased water infiltrations and mortar applications, the supports can be prepared for grouting repair. Both mortar and epoxy resin can be used.

| Tube dimensions | circular profile main pipe: 200-600 mm service connection: 70-200 mm |

| Weight | 40 kg |

| Drive | manual feed |

| Swivel drive | electrical |

| Contact pressure | 12,700 N |

| Length of supply cable | 70 m |

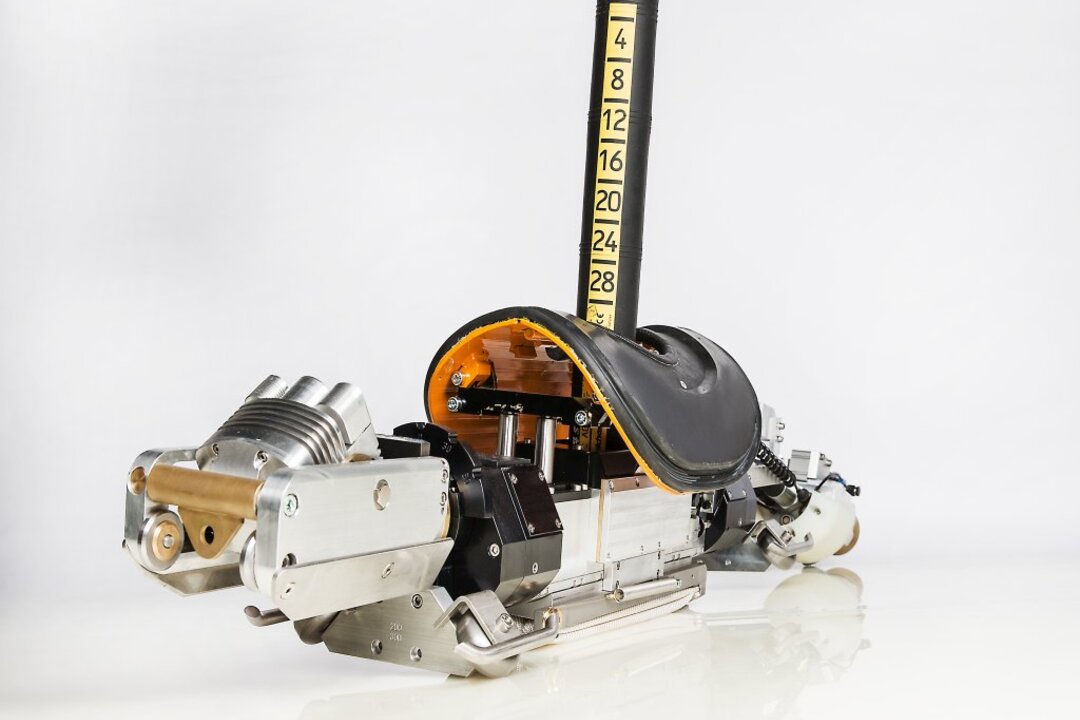

Silicone saddle and control case for resin application

The heated silicone saddle is used for the grouting of epoxy resin. For this purpose, the resin is filled into metal containers and carried in a cartridge. Note that grouting is only allowed in a dry environment. It is operated with the respective control case for resin application.

- Control via resin control case

- Electrical connection via plug (230 V)

- Hardening time: 1 hour

- Resin quantity carried: 3 litres

- Tube dimensions: 200-600 mm

- Weight: 7.5 kg

Fully automatic squeeze out and mixing unit AP4

Fully automatic squeeze out and mixing unit for four bags

of resin and hardener.

- electrically driven via 230 volt alternating current

- better dosing in comparison to pneumatic squeeze out and mixing units (no dripping)

- low costs for compulsory mixers

- much smaller than other pneumatic squeeze out and mixing units

- dimensions (W x D x H) 305 x 240 x 1120 mm

- spring-supported lid unit for an easier change of bags

- very high extrusion force

- 4 tubular bags with 700 ml